Auto Glass Tech: Future Innovations Unveiled

The automotive industry stands at the precipice of a technological revolution, and nowhere is this transformation more evident than in auto glass technology. What was once simple transparent panels has evolved into sophisticated smart systems that enhance safety, comfort, and driving experience. Modern vehicles now feature electrochromic glass, heads-up displays integrated into windshields, and sensor-laden surfaces that communicate with vehicle systems in real-time. These innovations represent a fundamental shift in how we think about automotive components, transforming glass from a passive barrier into an active participant in vehicle intelligence.

The convergence of materials science, software engineering, and automotive design has created unprecedented opportunities for innovation. Manufacturers are investing billions into research and development, pushing the boundaries of what auto glass can accomplish. From self-healing surfaces to augmented reality windshields, the future of auto glass technology promises to revolutionize how we drive, navigate, and interact with our vehicles. Understanding these emerging technologies provides insight into the broader transformation reshaping the automotive landscape, much like how artificial intelligence is transforming our future.

Smart Glass Technology and Electrochromic Innovations

Electrochromic glass represents one of the most significant breakthroughs in automotive transparency technology. Unlike traditional tinted glass that relies on physical coatings, electrochromic glass uses electrical current to change its light transmission properties instantly. When voltage is applied to the glass, ions move within a thin layer between glass panes, darkening or lightening the surface on demand. This technology eliminates the need for traditional sunroofs and allows drivers to control light penetration with precision, reducing cabin temperature and glare without sacrificing visibility.

The advantages of smart glass extend beyond comfort. By controlling solar heat gain, electrochromic glass reduces the load on air conditioning systems, directly improving fuel efficiency and reducing emissions. Major manufacturers including Tesla and premium automakers are integrating this technology into their flagship models. The glass responds to various triggers: ambient light sensors, driver preference settings, or automated schedules. Some advanced systems even coordinate with vehicle climate control, creating an integrated thermal management system that optimizes energy consumption throughout the cabin.

Current electrochromic glass implementations achieve full opacity changes in 2-3 seconds, with response times improving continuously. The technology maintains structural integrity while providing optical clarity, and manufacturers report durability ratings exceeding 200,000 activation cycles. Integration with vehicle software allows for customizable tinting schedules—automatically darkening during peak sun hours or brightening when interior lighting is needed. This smart glass technology exemplifies how modern tech innovations are reshaping vehicle design.

Integrated Heads-Up Displays and AR Windshields

Augmented reality windshields represent the frontier of automotive glass technology, transforming the windshield into an interactive information display. Rather than requiring drivers to glance at dashboard screens, AR windshields project critical information directly into the driver’s line of sight. Navigation arrows appear overlaid on actual road intersections, speed limits display at appropriate locations, and hazard warnings highlight potential obstacles. This technology reduces cognitive load and keeps drivers focused on the road ahead.

The technical implementation involves micro-LED or laser projection systems mounted behind the windshield, with specially treated glass surfaces that allow light to pass through while serving as projection screens. Advanced versions use waveguide technology to create holographic-like displays that appear to float at specific distances from the driver’s eyes. These systems process data from vehicle sensors, GPS systems, and connected services to provide real-time, contextually relevant information. Manufacturers like BMW and Mercedes-Benz have already deployed heads-up display systems in production vehicles, with AR capabilities expanding rapidly.

The integration of heads-up displays with vehicle automation systems creates powerful synergies. Autonomous driving systems can use the windshield to communicate intentions to other road users, displaying directional arrows or warning symbols visible to pedestrians and cyclists. The glass becomes a communication interface between vehicle and environment. Future iterations will incorporate eye-tracking technology, allowing displays to adjust based on driver gaze direction and cognitive attention patterns. This represents a crucial step toward seamless human-vehicle interaction.

Advanced Sensor Integration in Glass Surfaces

Modern auto glass is evolving from a passive structural component into an active sensor platform. Embedded optical sensors can detect rain, automatically triggering windshield wipers, while proximity sensors measure distance to obstacles and vehicles ahead. Some advanced glass installations incorporate spectrographic sensors that analyze light wavelengths, enabling detection of road surface conditions, pedestrian presence, and environmental hazards. These sensors transmit data to vehicle control systems, informing autonomous driving decisions and safety interventions.

The challenge of integrating sensors into glass involves maintaining optical clarity while incorporating functional elements. Manufacturers use thin-film deposition techniques to create sensor arrays that are virtually invisible to the human eye. These microscopically thin layers can detect motion, measure ambient light intensity, sense humidity, and even monitor structural integrity. The sensors communicate wirelessly with vehicle electronics, eliminating the need for complex wiring harnesses that would otherwise compromise glass strength and transparency.

Thermal imaging sensors embedded in windshields enable night vision capabilities, displaying pedestrians and animals on the heads-up display even in complete darkness. Some luxury vehicles already feature this technology, significantly enhancing safety during nighttime driving. The integration of multiple sensor types creates redundant systems where glass surfaces serve as primary sensing elements, reducing the need for additional external sensors and improving vehicle aerodynamics. This multifunctional approach to glass design reflects broader trends in technology transforming automotive systems.

Self-Healing and Durable Glass Materials

Self-healing glass technology addresses one of automotive glass’s most persistent problems: cracks and chips from road debris. Researchers have developed glass formulations incorporating embedded polymer networks that can automatically seal small fractures. When micro-cracks form, the polymer material flows into the damaged area, bonding glass fragments together and restoring structural integrity. Laboratory tests demonstrate that small cracks (up to 3mm) can be completely healed within minutes, without requiring any external intervention.

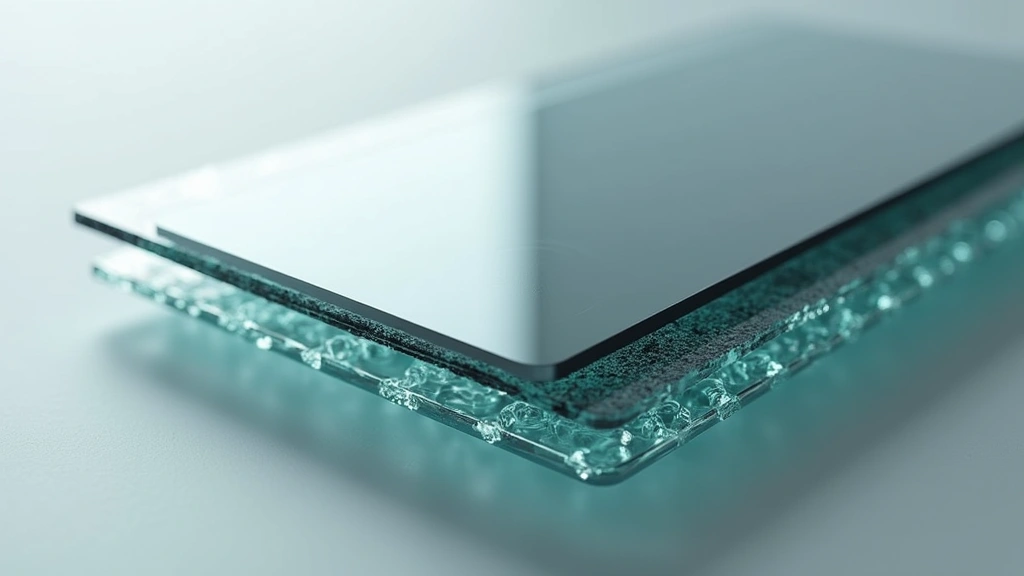

The chemistry behind self-healing glass involves incorporating capsules of healing agents throughout the glass matrix. When cracks propagate through the material, they rupture these capsules, releasing healing compounds that chemically bond fractured surfaces. Advanced formulations use thermally triggered healing mechanisms that activate when glass temperature rises from friction during crack propagation. These materials maintain all the optical properties of conventional glass while dramatically extending service life.

Durability improvements extend beyond self-healing capabilities. New glass compositions demonstrate enhanced resistance to thermal shock, reducing the likelihood of spontaneous cracking from extreme temperature variations. Impact-resistant formulations use laminated structures with specialized interlayer materials that absorb energy more effectively than traditional safety glass. Some manufacturers are experimenting with graphene-reinforced glass, which exhibits dramatically improved strength-to-weight ratios. Corning and other materials science leaders continue advancing glass formulations that promise longer service life and reduced replacement costs.

Thermal Management and Climate Control

Auto glass technology is becoming central to vehicle thermal management systems. Photochromic and thermochromic glass automatically adjusts tinting based on solar intensity or temperature, reducing interior heat gain and decreasing air conditioning demand. Some advanced systems incorporate phase-change materials within glass layers that absorb excess heat when temperatures rise and release stored heat when temperatures drop, maintaining more stable cabin temperatures with minimal energy input.

The integration of thermal management into glass creates cascading efficiency improvements. Reduced air conditioning load directly translates to improved fuel economy and extended driving range in electric vehicles. In cold climates, smart glass can concentrate solar heat into the cabin, reducing heating system demands. These passive thermal management systems work continuously without requiring active energy input beyond the initial electrical charge for electrochromic tinting.

Advanced thermal glass also improves passenger comfort by reducing hot spots and cold zones that occur with conventional glass. Special coatings reflect infrared radiation while maintaining visible light transmission, creating more uniform temperature distribution throughout the cabin. The technology proves particularly valuable in autonomous vehicles where climate control becomes a critical factor in passenger comfort during extended rides. Manufacturers report that integrated thermal glass systems reduce overall vehicle energy consumption by 5-15%, depending on climate and driving patterns.

Enhanced Safety Features and Impact Resistance

Safety has always been central to automotive glass design, but new technologies are creating unprecedented protection levels. Laminated glass with advanced interlayer materials maintains structural integrity even when shattered, preventing occupants from being ejected during collisions. Some formulations incorporate airbag-compatible designs that allow airbags to deploy through the glass while maintaining structural support.

Impact detection systems embedded in windshields can identify collision severity and communicate with vehicle safety systems in real-time. These systems trigger appropriate responses—from airbag deployment timing to seatbelt tensioning—based on actual impact characteristics rather than relying solely on accelerometer data. The glass essentially becomes a primary sensor for collision detection, providing more accurate information than traditional methods.

Pedestrian protection features are emerging as another critical safety application. Some glass designs incorporate energy-absorbing properties that reduce injury severity when pedestrians are struck. The glass deforms to absorb impact energy rather than transmitting force directly to the underlying vehicle structure. This technology addresses regulatory requirements in markets like Europe where pedestrian impact protection standards continue to become more stringent.

Manufacturing Advances and Production Techniques

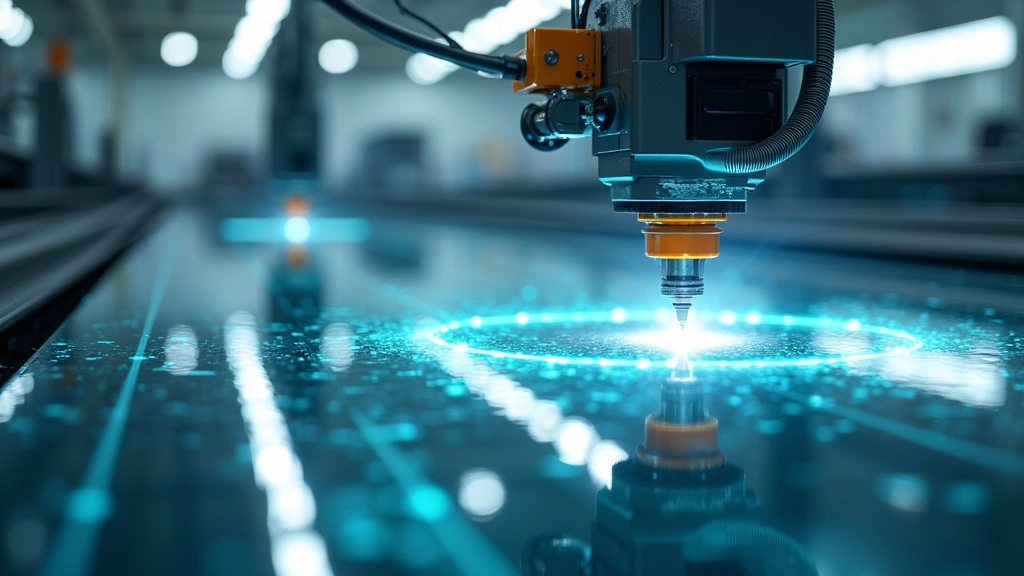

The production of advanced auto glass requires revolutionary manufacturing approaches. Traditional float glass processes cannot accommodate the complex layer structures and embedded components modern glass demands. Manufacturers are adopting roll-to-roll production techniques that allow continuous processing of multi-layer glass with integrated sensors and functional coatings. These automated systems achieve unprecedented precision while reducing costs as production volumes scale.

Vacuum deposition techniques enable manufacturers to apply microscopically thin functional layers to glass surfaces without affecting optical properties. Magnetron sputtering creates uniform coatings of conductive materials, semiconductors, and protective layers with atomic-level precision. Laser processing techniques cut intricate patterns for sensor integration while maintaining structural integrity. These advanced manufacturing methods represent significant capital investments but enable production of complex glass structures at competitive costs.

Quality control in advanced glass production requires sophisticated testing protocols. Optical inspection systems verify coating uniformity and detect microscopic defects that could compromise performance. Electrical testing confirms sensor functionality and embedded conductor integrity. Mechanical testing validates strength properties and impact resistance. These comprehensive quality assurance processes ensure that every glass unit meets exacting automotive standards before installation. The manufacturing innovations underlying modern auto glass production reflect broader advances in technology and engineering automation.

Market Adoption and Industry Timeline

The automotive glass technology market is experiencing rapid growth, with industry analysts projecting compound annual growth rates exceeding 8% through the next decade. Premium vehicle manufacturers are leading adoption, with electrochromic glass and heads-up displays becoming increasingly common in luxury segments. Mass-market adoption is accelerating as production costs decline and regulatory requirements incentivize advanced safety features.

Current market leaders include established glass manufacturers like Saint-Gobain, AGC, and Fuyao, alongside newer entrants focused specifically on smart glass technologies. Automotive OEMs are developing proprietary glass solutions tailored to their vehicle platforms, creating competitive differentiation in premium segments. Supply chain investments are substantial, with manufacturers establishing new production facilities specifically designed for advanced glass manufacturing.

The regulatory environment is driving technology adoption forward. Safety standards increasingly mandate advanced sensor systems and impact detection capabilities that glass-integrated solutions can provide cost-effectively. Environmental regulations favor technologies that reduce vehicle energy consumption, making thermal management glass particularly attractive. Future autonomous vehicle regulations will likely require sophisticated sensor integration and driver communication systems that advanced auto glass technologies naturally support.

FAQ

What is electrochromic auto glass and how does it work?

Electrochromic glass uses electrical current to change light transmission properties. When voltage is applied, ions move within glass layers, darkening or lightening the surface instantly. The technology eliminates traditional sunroofs and reduces air conditioning loads by controlling solar heat gain. Response times are typically 2-3 seconds for full opacity changes, with systems rated for over 200,000 activation cycles.

Are heads-up displays safe for drivers?

Yes, modern heads-up displays are designed to minimize driver distraction by presenting information directly in the driver’s line of sight. The displays appear at distances that don’t require eye refocusing, keeping drivers focused on the road. Studies show that properly implemented heads-up displays actually reduce reaction times compared to dashboard-mounted screens.

How durable is self-healing glass?

Self-healing glass can seal micro-cracks up to 3mm within minutes without external intervention. The technology extends service life significantly by preventing crack propagation. However, major damage from severe impacts still requires glass replacement—self-healing technology addresses minor road debris damage rather than catastrophic failures.

What is the cost difference for smart glass versus conventional auto glass?

Advanced auto glass typically costs 20-50% more than conventional glass, depending on specific features and vehicle platform. However, fuel efficiency improvements and extended service life often offset the initial premium over the vehicle’s lifetime. As production scales, price premiums are expected to decrease significantly.

When will augmented reality windshields become standard?

AR windshields are already available in premium vehicles from BMW, Mercedes-Benz, and other luxury manufacturers. Mass-market adoption is expected within 5-7 years as production costs decline and autonomous driving regulations create demand for advanced driver communication systems. Early adopters in 2024-2025 are establishing the technology foundation for broader implementation.

How do embedded sensors affect glass strength?

Modern sensor integration techniques use thin-film deposition that maintains glass structural integrity while adding functionality. The embedded components are microscopically thin and don’t compromise impact resistance or optical clarity. Glass with integrated sensors meets or exceeds all automotive safety standards.